Embroidery machines are a recent addition to Sublistar. Although embroidery machines have long existed, there are few combinations of DTF printing and embroidery printing. This innovative application can greatly meet the more diverse individual needs of customers.

Next, we will narrate the embroidery machine.

The Sublistar embroidery machine belongs to a type of computer embroidery machine. By automated printing, the output of an efficient, accurate and delicate textile can be combined with DTF printing to make it more vivid and appealing.

What are the characteristics of Sublistar embroidery machines?

1.Support for diversified embroidery

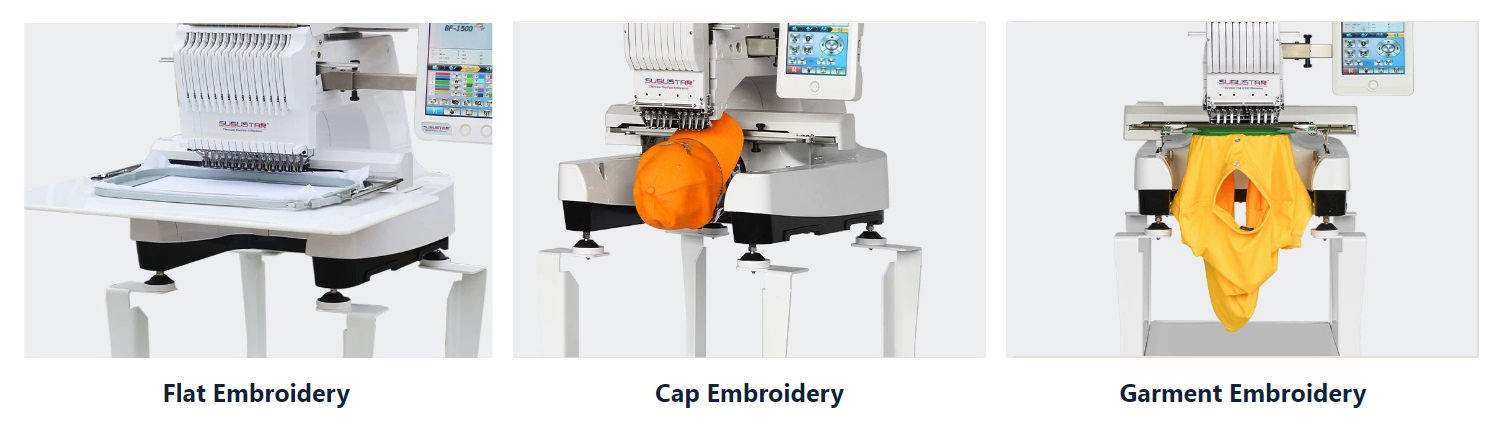

With its ability to incorporate flat, garment, and cap embroidery, the SUBLISTAR small entry-level single-head digital embroidery machine allows for a maximum embroidery area of 360 by 200 mm. This machine truly embodies multi-functionality. The lightweight and compact design of the single-head machine saves room. Simple to use and run without a hitch.

2. Hd smart display

Using 10-inch digital color LCD touch screen, clear operation page, make the operation easier, configure multiple USB interfaces, support 12 language switching, to meet the production needs of many countries. If you have more needs, you can contact Sublistar for personal customization.

3.LED fluorescent lamp

Equipped with LED fluorescent lamps, the use of high brightness lamp beads, eye protection at the same time, but also to ensure that the embroidery threading is convenient, so that the output of the finished product will be more clear.

4. Advanced imported parts

Japanese Imported Rotary Shuttle, Original imported Zomon shuttle, continuous embroidery without thread breakage, no replacement for three years. Real-time Camera Positioning, with the built-in high-definition camera, you can observe the fabric in real time on the screen, and it helps you to accurately position the embroidery pattern to the desired position.

5.Auto Embroidery

Equipped with infrared laser positioning light, infrared laser to determine the needle point, embroidery position is more accurate. After the instructions of the computer side, automatic embroidery, automatic threading, automatic cutting, automatic color change, automatic wire break detection can be automated.

What are the main advantages of Embroidery machines?

1. High speed and efficiency

High-speed embroidery: The embroidery machine can achieve high-speed embroidery, which greatly improves the production efficiency. Compared with traditional hand embroidery, the embroidery machine can complete a large number of embroidery work in a shorter time.

Continuous operation: the embroidery machine can work continuously for a long time, and is not limited by human fatigue, which further improves the production efficiency.

2. High precision and high quality

Precise control: Through the advanced control system, the embroidery machine can precisely control the motion trajectory and strength of the embroidery needle, so as to achieve high-precision embroidery.

High quality embroidery: Due to the precise control of the embroidery machine, the embroidery pattern has smooth lines, bright colors and distinct layers. Of course, if it has Chinese characteristics, there are still differences between the embroidery of non-inherited craftsmen. After all, people’s culture and skills have been passed down for thousands of years, with irreplaceable uniqueness.

3. Versatility and variety

A variety of embroidery methods: the embroidery machine can not only carry out flat embroidery, but also achieve a variety of embroidery methods such as gold sheet embroidery, towel embroidery, ribbon embroidery, etc., to meet different embroidery needs.

Various patterns: embroidery machine can embroider a variety of complex patterns, including text, patterns, portraits, etc., and the pattern design is flexible and changeable.

4. Automation and intelligence

Automatic color change: The embroidery machine has an automatic color change function, which can automatically change the embroidery thread of different colors according to the pattern needs, reducing manual intervention.

Intelligent control: Some high-end embroidery machines also have intelligent control functions, such as automatic break detection, automatic cutting, automatic compensation, etc., which further improves production efficiency and embroidery quality.

5. Economy and environmental protection

Cost saving: the high-speed and efficient characteristics of embroidery machine greatly reduce the production cost and save human and material resources for enterprises.

Energy saving and emission reduction: With the continuous progress of technology, modern embroidery machines have also achieved remarkable results in energy saving and emission reduction, in line with the requirements of green production.

6. Wide applicability

Wide range of application: the embroidery machine is suitable for all kinds of textile embroidery processing, such as clothing, home textiles, shoes and hats, crafts, etc., has a wide range of application prospects.

Meet different needs: The embroidery machine can be customized according to customer needs, to meet the diversified embroidery needs in the market.

Why should DTF printing and embroidery printing be combined?

At present, there are too many similar products on the market, homogenization is very serious, and many businesses are facing huge challenges. If you don’t innovate, you will walk down an increasingly narrow path. Only by constantly innovating and launching products that make customers more satisfied, customers are likely to choose your products.

The combination of DTF printing and embroidery can enable customers to get more different visual experiences on the same product. Colleagues who enjoy the bright and clear finished products printed by DTF can also experience the exquisite and delicate from the embroidery. The combination of the two will be a collision between design and beauty!

Customers can discuss with the designer, and DTF’s personalized customization, design a unique combination of their own, amazing!

Of course, the combination of the two can also fully prove that the level of clothing printing technology is constantly improving, and can meet the needs of the market to a greater extent. embroidery prints can be widely used in the production of textiles such as garments, home textiles and ornaments, which adds a unique artistic value and market competitiveness to these products.

Therefore, embroidery machine still has broad prospects and productivity in the present. If it is combined with DTF printing, it will be the birth of a new printing force, bringing more beautiful experience and visual enjoyment to the majority of users!